High temperature tungsten heavy alloys

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 10pcs |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-055

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

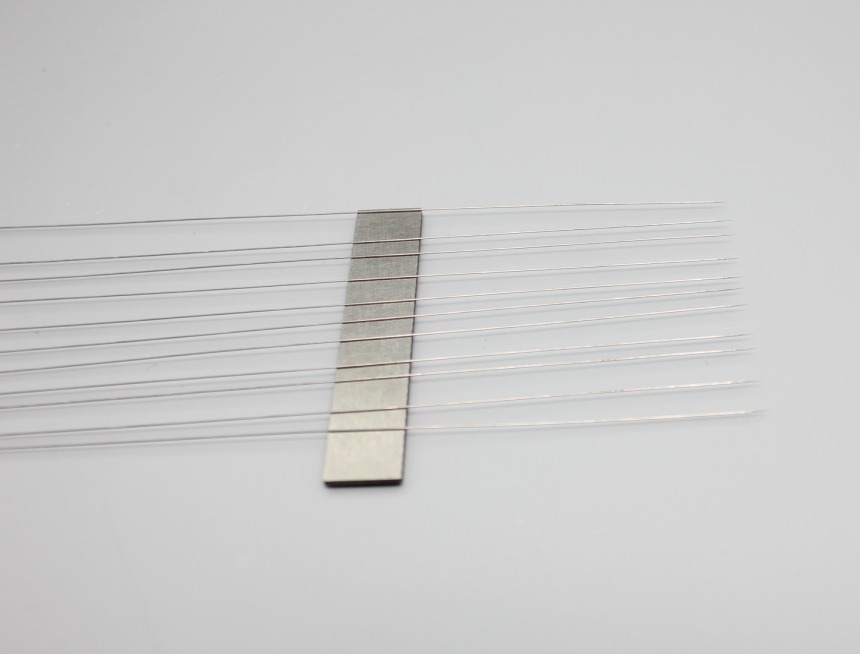

Material: 85-99% Tungsten

Denstiy: 15.8-18.75 g/cm3

Surface: Sintered, Forged, Grounded

PACKAGING & DELIVERY

Selling Units : Kilogram

Package Type : Standard export packing

DESCRIPTION

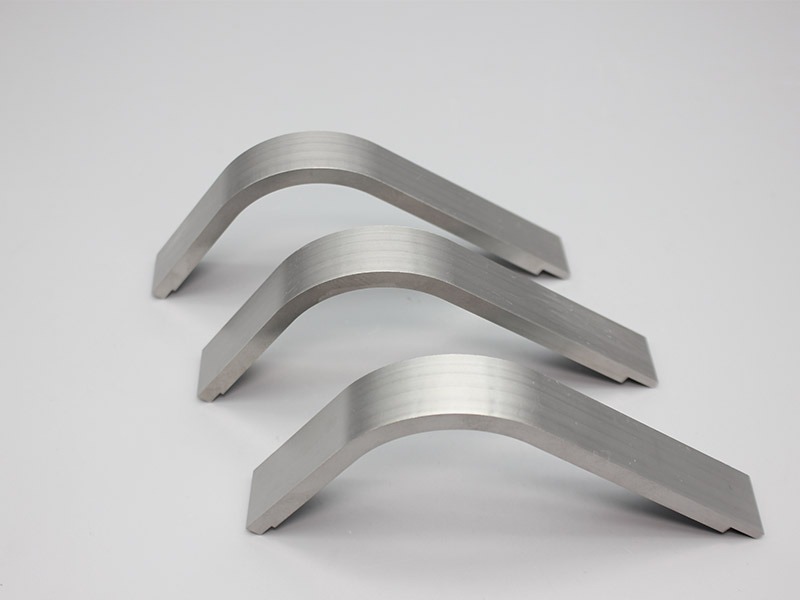

Customizing tungsten alloy components according to technical drawings is a specialized process that requires precision engineering and manufacturing expertise. Here's a comprehensive overview of how we approach custom tungsten alloy parts based on your drawings:

Our Customization Process

Drawing Analysis

Our engineers review your 2D/3D drawings (DXF, DWG, STEP, IGES) to assess:

Geometry complexity (holes, threads, grooves, tolerances).

Material grade requirements (WNiFe, WCu, WC-Co, pure W).

Density specifications (17.0–19.3 g/cm³).

Surface finish (as-sintered, ground, polished).

Material Selection

Alloy Type Key Properties Best For

WNiFe (90-97% W) High density, good machinability Counterweights, shielding

WCu (70-90% W) High thermal/electrical conductivity Heat sinks, EDM electrodes

WC-Co (85-94% WC) Extreme hardness, wear resistance Cutting tools, nozzles

Pure Tungsten Highest melting point (3422°C) High-temperature furnaces

Manufacturing Methods

Powder Metallurgy: Pressing + sintering for near-net shapes.

CNC Machining: Carbide tools for tight tolerances (±0.005mm).

Grinding/EDM: For precision features and fine finishes (Ra ≤0.1µm).

Quality Control

Density Verification: Archimedes’ method (ASTM B311).

Dimensional Inspection: CMM, optical comparators.

Material Certification: Mill test reports (composition, density, hardness).

Technical Capabilities

Parameter Capability

Max. Part Size 500mm x 500mm x L (via HIP)

Tolerance ±0.005mm (machining), ±0.1mm (as-sintered)

Surface Finish Ra 0.1µm (mirror polish)

Density 17.0–19.3 g/cm³ (adjustable via alloy ratio)

Post-Processing Ni-plating, TiN coating, passivation

Industries Served

Aerospace: Gyroscope rotors, flight control counterweights.

Medical: Radiation shielding collimators, isotope containers.

Defense: Kinetic energy penetrators, armor components.

Energy: Nuclear reactor shielding, fuel rod spacers.

Industrial: EDM electrodes, boring bars, precision fixtures.

Why Choose Our Custom Service?

Expertise: 15+ years in tungsten alloy manufacturing.

Fast Prototyping: 1-2 weeks for samples (with drawing approval).

Full Certification: ISO 9001, ITAR, RoHS compliance.

Global Shipping: DDP terms for seamless logistics.

How to Get Started

Send Your Drawings (to [email protected]).

Receive a Quote within 24 hours (including material, process, and lead time).

Approve Prototyping (we manufacture and inspect samples).

Mass Production (bulk orders with batch testing reports).

Free DFM (Design for Manufacturing) Analysis: Our engineers optimize your design for cost-effective production.

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU