High-Performance Sealing Solutions: Tungsten ball

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW,FCA,Express Delivery |

| Min. Order: |

2 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-046

Brand: ZZJD

Place Of Origin: China

Material: Tungsten

Density: 18.10±0.15g/cm³

Color: Natural

Size: Support customization

PACKAGING & DELIVERY

Selling Units :Piece/Pieces

Package Type : Standard export packing

DESCRIPTION

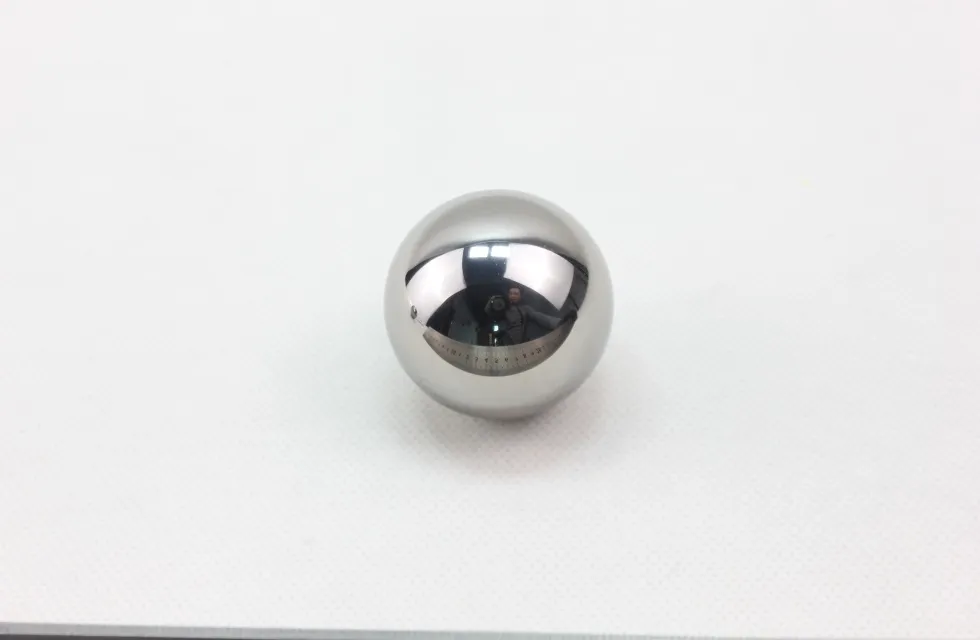

Tungsten Alloy Valve Balls – High-Performance Sealing Solution

Why Tungsten Alloy?

Tungsten carbide (WC) or heavy alloy (WNiFe/WCu) valve balls outperform steel, ceramic, and plastic in extreme conditions due to:

Ultra-High Hardness (HRA 90+) – Resists abrasive slurries, scaling, and particle erosion.

Corrosion Resistance – Withstands acids, alkalis, and seawater (pH 1–14).

Density (14–15 g/cm³) – Improves shut-off pressure ratings (ANSI Class VI sealing).

Thermal Stability (-200°C to +600°C) – No deformation in cryogenic or high-temp processes.

Product Range

Type Material Key Features Applications

Tungsten Carbide Balls WC-Co (6–12% Co) Extreme wear resistance Oil/gas choke valves, mining

Heavy Alloy Balls WNiFe (93–97% W) Machinable, good impact toughness Chemical processing, marine

Plated Tungsten Balls WC with CrN/DLC coating Low friction, anti-galling Food/pharmaceutical valves

Technical Specifications

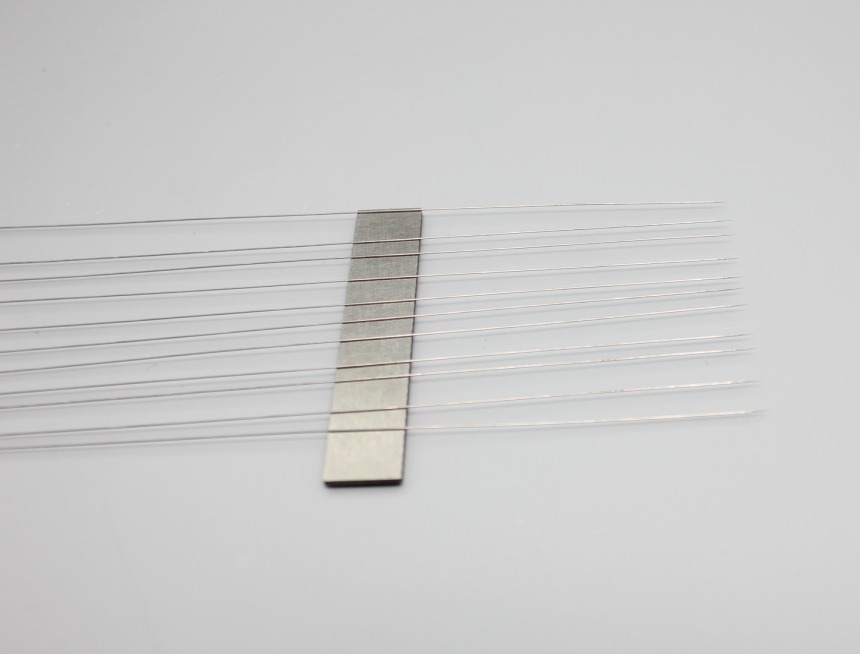

Sizes: 5mm – 150mm diameter (±0.001mm tolerance)

Surface Finish: Ra ≤0.025µm (mirror polish for bubble-tight sealing)

Pressure Rating: Up to 10,000 PSI (690 bar)

Certifications: API 6A, ASME B16.34, ISO 9001

Industry Applications

Oil & Gas: Subsea BOP valves, wellhead control

Chemical: Chlor-alkali processing, sulfuric acid lines

Power: Nuclear reactor coolant systems

Marine: Ballast/seawater injection valves

Performance Comparison

Property Tungsten Carbide Stainless Steel 316 Ceramic (Al₂O₃)

Hardness (HV) 1500–1800 200–250 1200–1400

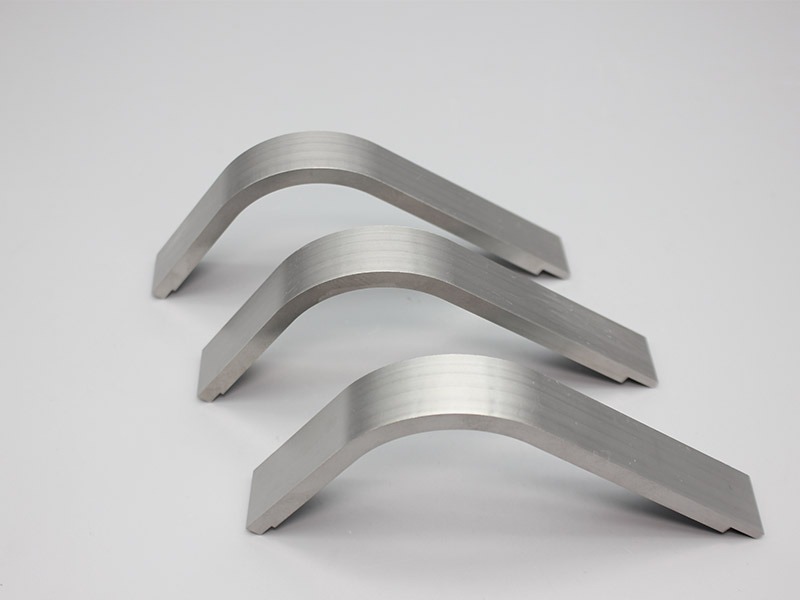

Custom Options

Hollow Design: Weight reduction for large-diameter balls

Precision Grinding: Sphericity ≤0.5µm for zero leakage

Testing: Helium leak test, 3D roundness analysis

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU