Tungsten alloy high-temperature nozzle

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW,FCA,Express Delivery |

| Min. Order: |

1 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-052

Brand: ZZJD

Place Of Origin: China

Material: Tungsten

Density: 18.10±0.15g/cm³

Color: Natural

Size: Support customization

PACKAGING & DELIVERY

Selling Units :Piece/Pieces

Package Type : Standard export packing

DESCRIPTION

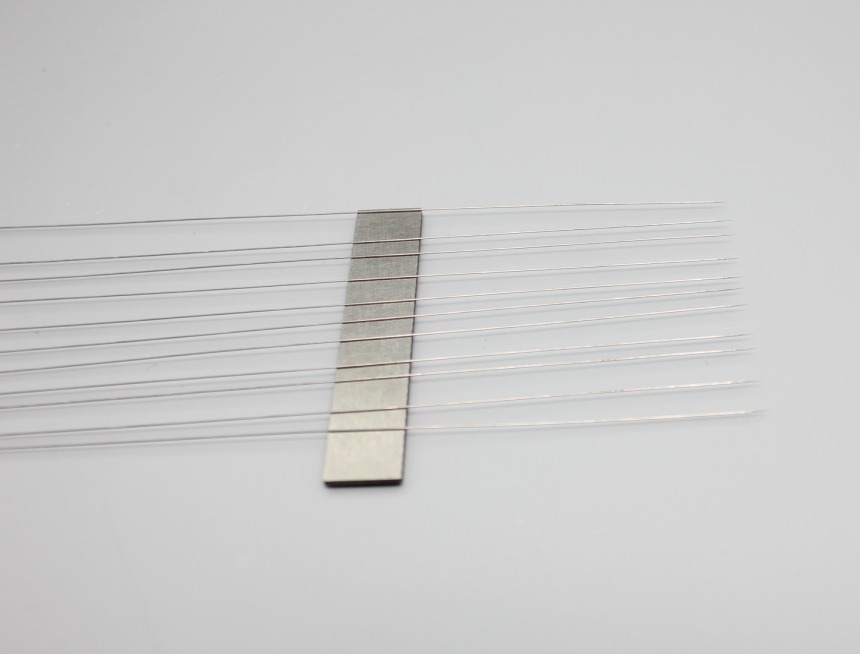

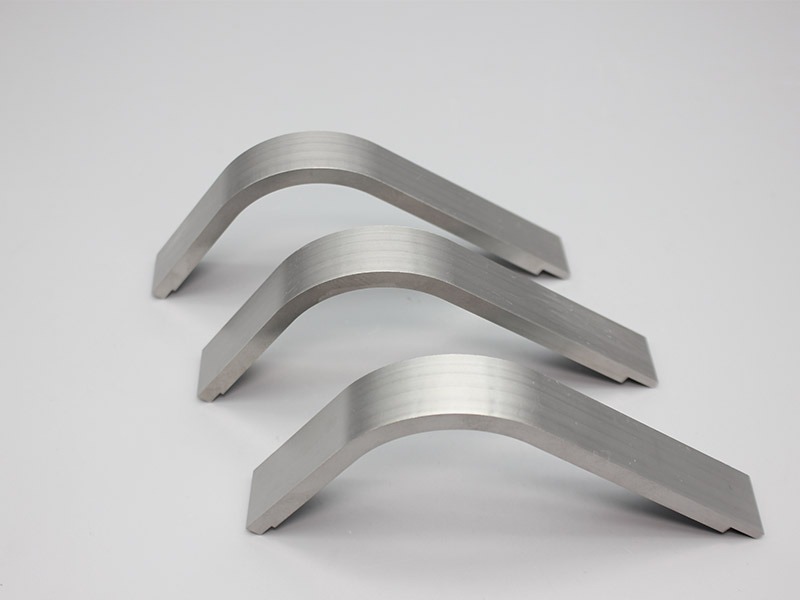

Tungsten Alloy High-Temperature Nozzles – Extreme Environment Fluid Control Solutions

Why Tungsten Alloy?

Tungsten heavy alloys (WNiFe, WCu, WMo) are ideal for ultra-high-temperature nozzles due to:

Melting Point (3,422°C) – Withstands plasma arcs, rocket exhaust, and molten metal splashes.

Abrasion Resistance – 10X longer lifespan than steel in particle-laden flows (e.g., thermal spray, sandblasting).

Thermal Shock Stability – Minimal cracking under rapid heating/cooling cycles.

Corrosion Resistance – Performs in acidic, alkaline, and oxidizing environments.

Product Range

Nozzle Type Material Max Temp. Key Applications

Plasma Spray Nozzles WC-Co (88% W) 2,800°C Aerospace coatings, turbine blade repair

Rocket Injectors WCu (70% W) 3,000°C Liquid propellant combustion chambers

Molten Metal Nozzles WNiFe (95% W) 1,600°C Continuous casting (steel, titanium)

Sandblasting Nozzles WC-6%Co 800°C Surface preparation, shipyard grit blasting

Chemical Jet Nozzles WMo Alloy 1,200°C Acid etching, semiconductor cleaning

Technical Specifications

Bore Sizes: 0.5mm – 50mm (±0.005mm tolerance for precision jets)

Surface Finish: Ra ≤0.1µm (mirror polish for laminar flow)

Pressure Rating: Up to 50,000 PSI (3,450 bar) for waterjet cutting

Cooling Options:

Internal Channels (liquid/gas cooling)

Copper-Backed (WCu for heat dissipation)

Performance Comparison

Property Tungsten Nozzle Stainless Steel Ceramic (SiC)

Max Temp. 3,000°C+ 1,400°C 1,800°C

Wear Rate 0.01 mm³/hour 0.5 mm³/hour 0.1 mm³/hour

Thermal Conductivity 110 W/mK (WCu) 15 W/mK 120 W/mK

Industry Applications

Aerospace: Plasma spray coating of thermal barriers (TBCs)

Energy: Coal gasifier nozzles, nuclear fuel rod fabrication

Metalworking: Laser cutting assist gas nozzles

Semiconductors: Wafer cleaning with high-purity chemical jets

Customization Options

Bore Geometry: Convergent-divergent (de Laval), straight, or multi-orifice designs

Coatings: Alumina/TiN for additional oxidation resistance

Threads/Flanges: NPT, ISO, or proprietary quick-connect systems

#HighTempNozzle #TungstenEngineering #PlasmaSpray #RocketNozzle

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU