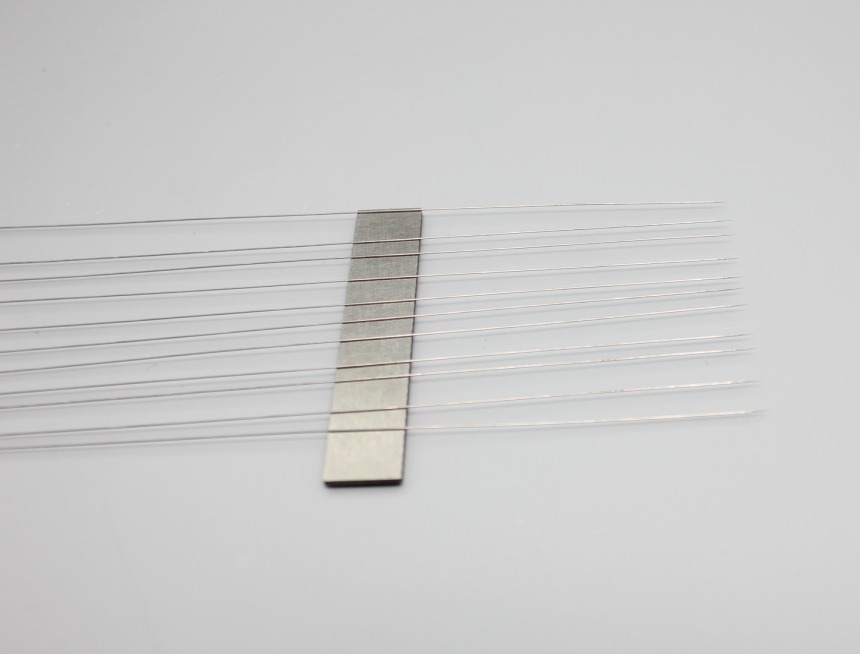

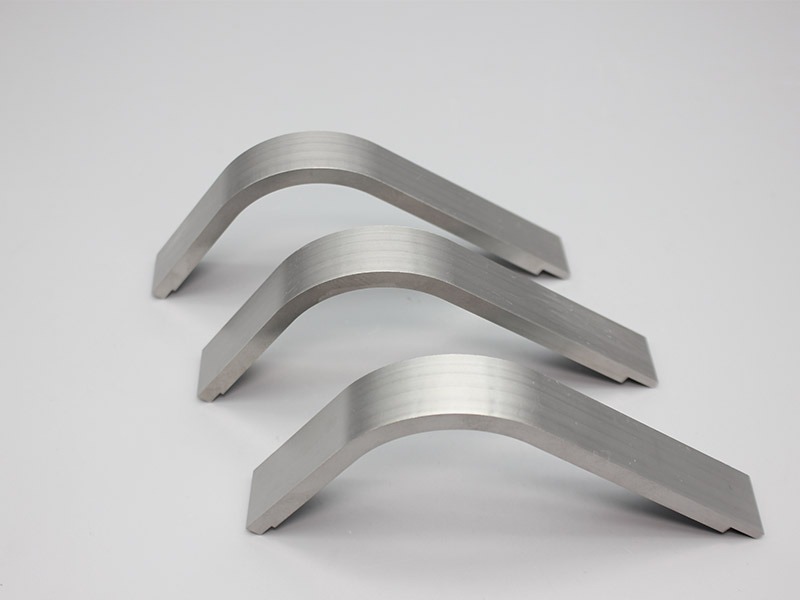

Tungsten heavy alloy bar

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 5PCS |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-058

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 85-99% Tungsten

Denstiy: 15.8-18.75 g/cm3

Surface: Sintered, Forged, Grounded

PACKAGING & DELIVERY

Selling Units : Kilogram

Package Type : Standard export packing

DESCRIPTION

Tungsten Alloy Bar – High-Density Precision Material for Demanding Applications

Product Overview

Tungsten Heavy Alloy (THA) bars are engineered materials primarily composed of Tungsten (W) (typically 90-97%) with a binder matrix of Nickel (Ni) and Iron (Fe) or Copper (Cu). They are renowned for their exceptional density, radiation shielding, and mechanical strength, making them indispensable in aerospace, defense, medical, and industrial sectors.

Key Properties & Advantages

Property Value / Description Advantage

Density 17.0 – 18.5 g/cm³ 50% denser than lead, 2.3x denser than steel. Ideal for space-efficient counterweights.

Hardness 28 – 32 HRC Excellent wear and abrasion resistance.

Tensile Strength 900 – 1200 MPa High strength under load, suitable for structural parts.

Thermal Conductivity 70 – 85 W/m·K (W-Ni-Fe) Effective for heat sinks and thermal management.

Corrosion Resistance Good (with Ni/Fe matrix) Resists oxidation and degradation in harsh environments.

Machinability Good (with carbide tools) Can be machined to precise tolerances, unlike pure tungsten.

Radiation Shielding Superior to lead Effective attenuation of X-rays and gamma rays.

Non-Toxic ROHS/REACH Compliant Environmentally safe alternative to lead and depleted uranium.

Common Alloy Grades

Alloy System Typical Composition Key Characteristics Best For

WNiFe 90-97W, balance Ni/Fe High strength, good ductility, machinable Counterweights, rotors, ordnance

WNiCu 90-97W, balance Ni/Cu Non-magnetic, good shielding MRI components, radiation shielding

WCu 70-80W, balance Cu Excellent electrical/thermal conductivity EDM electrodes, heat sinks

Primary Applications

Aerospace & Defense

Counterweights: Rotor blades, flight control surfaces, guidance systems.

Kinetic Energy Penetrators: Ordnance applications.

Gyroscopes: High-precision inertial components.

Medical & Radiation Shielding

Shielding Blocks: Collimators, syringe shields, PET/CT scanner parts.

Isotope Containers: Safe storage and transport of radioactive sources.

Industrial & Manufacturing

Tooling: High-wear fixtures, boring bars, and inserts.

Vibration Damping: Balancer shafts for high-speed machinery.

EDM Electrodes: (WCu) for precision electrical discharge machining.

Electronics

Heat Sinks: (WCu) for high-power semiconductor devices.

Standard Specifications

Parameter Standard Range Customization Available

Diameter 3mm – 150mm Up to 300mm+

Length Up to 600mm Up to 2000mm+

Tolerance ±0.05mm (drawn) / ±0.1mm (as-sintered) ±0.01mm (ground)

Surface Finish As-sintered, black oxide, ground, polished Ni-plating, Cu-plated

Density ≥ 17.0 g/cm³ Up to 18.5 g/cm³

Machining & Processing

Machining: Can be turned, milled, drilled, and tapped using carbide tools. Recommended slow speeds and high feed rates.

Grinding: Effective for achieving tight tolerances and fine finishes.

Joining: Can be brazed or welded using specialized techniques.

Heat Treatment: Response to heat treatment is limited; properties are primarily achieved through sintering.

Why Choose Our Tungsten Alloy Bars?

High-Quality Sintering: Uniform microstructure with >99% density and no voids.

Full Traceability: Mill test reports with chemical and physical property certification.

Precision Machining: In-house CNC and grinding capabilities for finished components.

Global Compliance: Meets ASTM B777, AMS 7725, and other international standards.

Expert Support: Engineering consultation for material selection and design.

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU