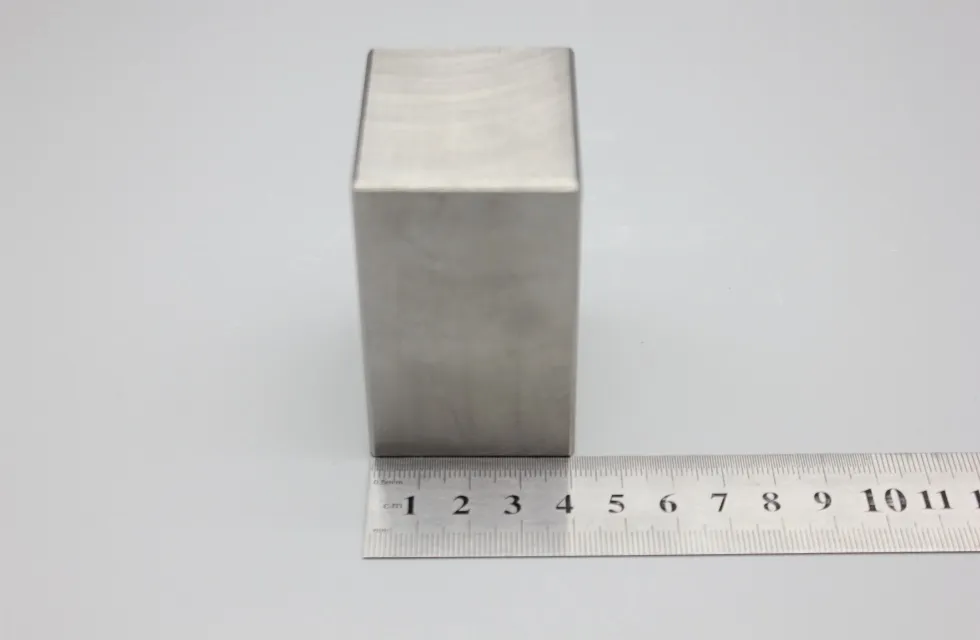

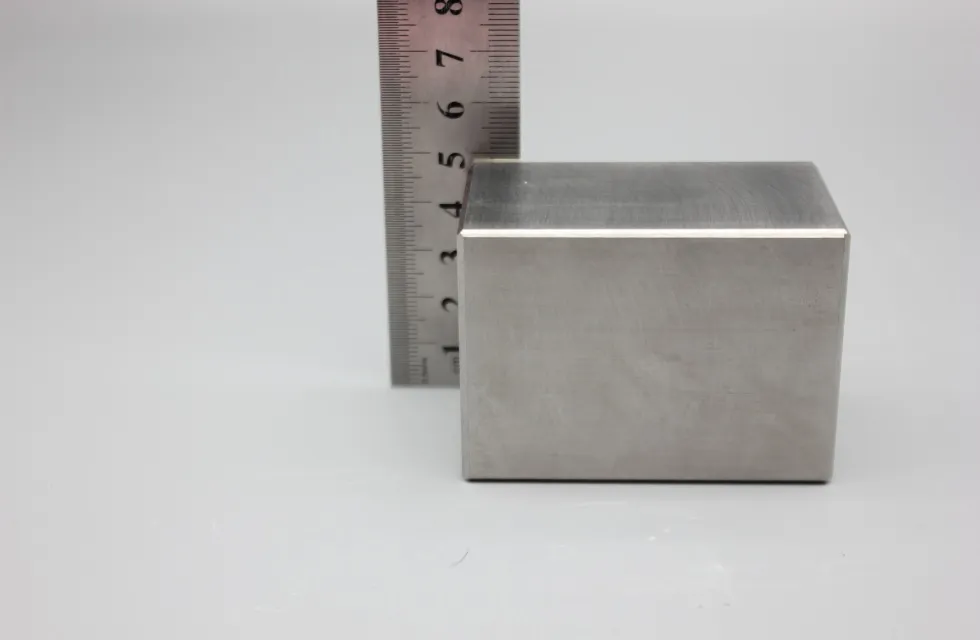

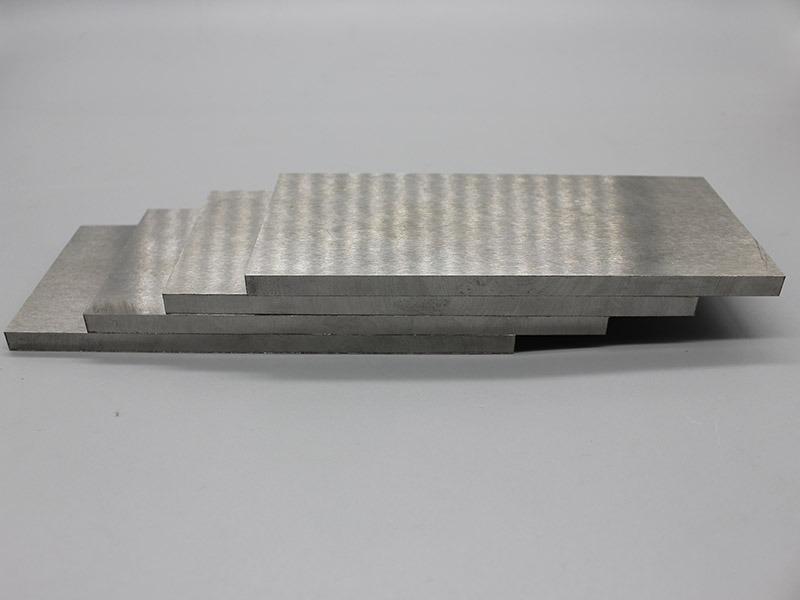

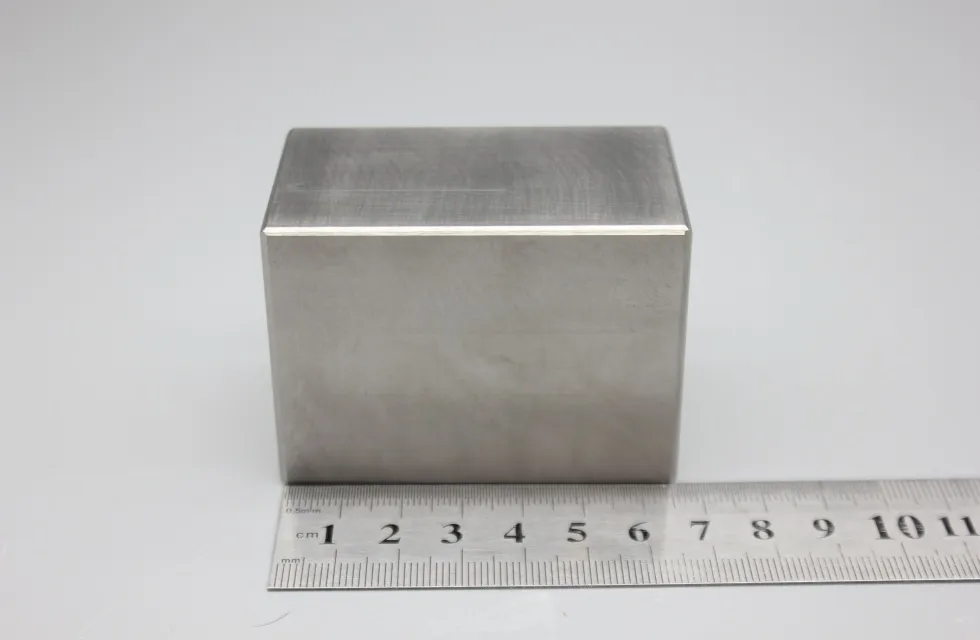

Custom tungsten alloy block-High-density tungsten alloy block

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 20 Kilogram |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-059

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 85-99% Tungsten

Denstiy: 15.8-18.75 g/cm3

Surface: Sintered, Forged, Grounded

PACKAGING & DELIVERY

Selling Units : Kilogram

Package Type : Standard export packing

DESCRIPTION

High-Density Tungsten Alloy Block /Tungsten Alloy Brick– The Ultimate Material for Extreme Applications

High-density tungsten alloy blocks (typically WNiFe, WNiCu, or WMo compositions) are engineered materials with a density range of 17.0–19.3 g/cm³, offering unparalleled mass, strength, and stability. These blocks are precision-sintered and machined for critical applications where space efficiency and performance are paramount.

Key Features & Benefits

✅ Ultra-High Density – Up to 2.5X denser than steel and 50% denser than lead, enabling compact, heavyweight designs.

✅ Superior Shielding – Ideal for blocking X-rays, gamma rays, and neutrons in medical and nuclear environments.

✅ Exceptional Strength – High tensile strength (900–1200 MPa) and hardness (28–32 HRC) resist deformation under extreme loads.

✅ Machinability – Unlike pure tungsten, alloys can be machined into complex shapes using carbide tools.

✅ Corrosion Resistance – Withstands harsh chemicals, saltwater, and high temperatures.

Technical Specifications

Parameter Standard Range Custom Options

Material Grades WNiFe (90-97% W), WCu WMo, WNiCr

Density 17.0–18.5 g/cm³ Up to 19.3 g/cm³

Dimensions 10mm – 300mm (L/W/H) Larger sizes available

Tolerance ±0.05mm (as-sintered) ±0.01mm (ground)

Surface Finish As-sintered, ground Polished, Ni-plated

Primary Applications

Counterweights & Balancing

Aerospace: Rotor blades, satellite components, flight controls.

Automotive: Racing crankshafts, luxury vehicle damping systems.

Industrial: High-speed robotic arms, CNC machinery balancers.

Radiation Shielding

Medical: PET/CT collimators, syringe shields, isotope containers.

Nuclear: Reactor shielding, fuel rod handling tools.

Research: Particle accelerator beam stops, neutron absorbers.

Tooling & Wear Parts

EDM Electrodes: (WCu) for precision machining.

Boring Bars: Vibration damping in deep-hole drilling.

Molds & Dies: For high-pressure casting and extrusion.

Defense & Ballistics

Kinetic Energy Penetrators: Armor-piercing projectiles.

Vibration Damping: Firearm components for accuracy.

Comparison vs. Alternative Materials

Material Density (g/cm³) Radiation Shielding Machinability

Tungsten Alloy 17.0–19.3 ★★★★★ ★★★☆☆

Lead 11.3 ★★★★☆ ★★★★★

Steel 7.8 ★★☆☆☆ ★★★★★

Depleted Uranium 18.6 ★★★★★ ★☆☆☆☆

Customization Options

Alloy Tailoring: Adjust W/Ni/Fe ratios for optimal density/ductility balance.

Precision Machining: Holes, threads, grooves, and complex geometries.

Coatings: Ni-plating for corrosion resistance, DLC for wear resistance.

Certification: ISO 9001, ITAR, ASTM B777 compliance.

Why Choose Our Blocks?

High-Quality Sintering: Uniform density with >99.5% theoretical density and no voids.

Full Metrology: 3D CMM inspection ensures precise dimensions.

Rapid Prototyping: 2-week lead time for custom samples.

Global Logistics: DDP shipping to aerospace/defense hubs.

FAQs

Q: What is the maximum size available?

A: We can produce blocks up to 500mm x 500mm x L via isostatic pressing.

Q: Can tungsten blocks be welded?

A: Yes, using specialized techniques (e.g., electron beam welding).

Q: Are they RoHS compliant?

A: Absolutely! Our alloys are 100% lead-free and eco-friendly.

#TungstenBlock #RadiationShielding #Counterweight #HighDensityMaterial#Tungsten alloy bricks

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU